Pretreatment by Simultaneous Removal of SO2 and NO2 from Flue Gas

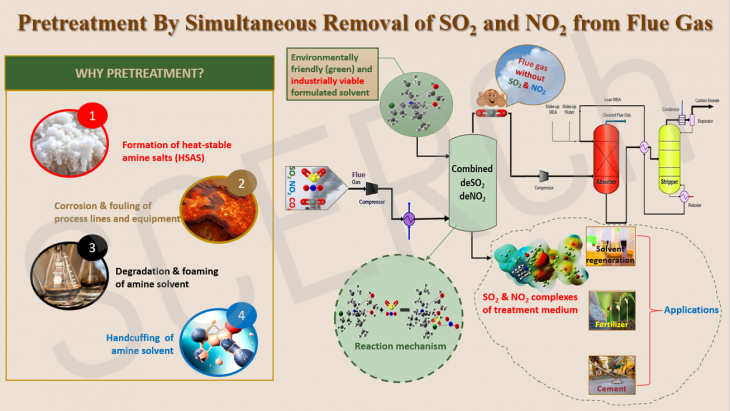

The global concern over climate change has led to the implementation of various measures to reduce greenhouse gas emissions, including carbon capture and storage (CCS) technology. One of the most promising CCS technologies involves the removal of CO2 from flue gas emitted by power plants and industrial processes, and either use or store it. However, the presence of sulfur dioxide (SO2) and nitrogen dioxide (NO2) in flue gas poses challenges to the efficient operation of amine-based CO2 capture systems. SO2 and NO2 in the flue gas does not only contribute to air pollution and acid rain but also, harm the CO2 capturing process by reacting with the amine to form Heat Stable Amine Salts (HSAS). HSAS causes corrosion, promote foaming and ‘handcuff’ the amine solution used for CO2 absorption.

Processes such as Selective Catalytic Reduction (SCR), Selective Non-catalytic Reduction (SNCR), and Flue Gas Desulfurization (FGD) are employed in industries to control SOx and NOx emissions. Nonetheless, with the deployment of these pollutant removal technologies, residual quantities of SO2 and NO2 remain in the flue gas entering the carbon capture system. For this reason, two of the major suppliers of CO2 capture plant, Fluor and Mitsubishi Heavy Industries (MHI), recommend limits for these contaminants in the flue gas entering the amine scrubber in other to minimize the detrimental effect of these impurities. Fluor suggested a SOx and NOx limits of 10 ppmv and 20 ppmv, and Mitsubishi Heavy Industries (MHI) discussed a SOx limit of 1–2 ppmv and a low but undefined NO2 limit (Reddy et al., 2008). As a result, to optimize the performance of amine-based CO2 capture systems, it is essential to develop effective pretreatment methods that enable simultaneous removal of SO2 and NO2 from flue gas before carbon capture with amine solvents.

Integrated wet scrubbing involves the use of tailored scrubbing solutions or suspensions that can effectively absorb both SO2 and NO2 simultaneously. This approach minimizes the need for separate treatment systems and reduces capital and operating costs. Additionally, combined sorbent-based systems utilize advanced sorbent materials capable of selectively capturing both SO2 and NO2 from flue gas. These materials exhibit high sorption capacities, selectivity, and stability, ensuring efficient removal of pollutants without compromising the performance of amine solvents in subsequent CO2 capture steps. Integration of these pretreatment techniques with amine-based CO2 capture systems can enhance overall process efficiency, reduce energy consumption, and minimize environmental impacts.

Our student will investigate the simultaneous NO2 and SO2 removal from flue gas using a novel, low-cost, and formulated green solvent. His study will emphasize the significance of optimizing operational parameters, such as temperature, residence time, and flue gas composition, to achieve efficient simultaneous removal of SO2 and NO2. The study will be conducted on a laboratory batch-scale using a simulated flue gas stream with varying concentrations of NO2 and SO2. Furthermore, empirical data generated from his work will be evaluated to study the performance and kinetics of the formulated solvent for further study.