Choice of Binder in Catalyst Preparation

Catalysts are employed in various industrial applications such as water purification, food, medical, cosmetology, automotive, gas purification, petroleum and precious metal recovery. Catalyst have the ability of speeding up the overall reaction without undergoing any permanent chemical change, as such, most catalyst are expected to be inert. All catalyst consist of an active phase, a support and a promoter or an inhibiter. When it comes to solid catalysts, one more component is key in obtaining the final catalyst; a binder!

Read More

Absorber Column Dimensions

When designing an absorber column to achieve the maximum efficiency, two things need to be determined, the diameter and the height of the column. In lame man’s terms, the diameter refers to how fat the column whereas the height refers to how tall the column will be. For starters, diameter relates to capacity, whereas height relates to the absorption rate...

Read More

Metal-Organic Frameworks for CO2 Capture

Developing an effective carbon dioxide capture system is essential to reducing greenhouse gas emissions and moving toward a cleaner energy future. As an emerging new class of porous solids, metal-organic frameworks (MOFs) adsorbents are particularly promising as CO2 capture materials because they have high internal surface areas, low heat capacity, and adjustable pore functionality enabling the selective adsorption of large quantities of CO2...

Read More

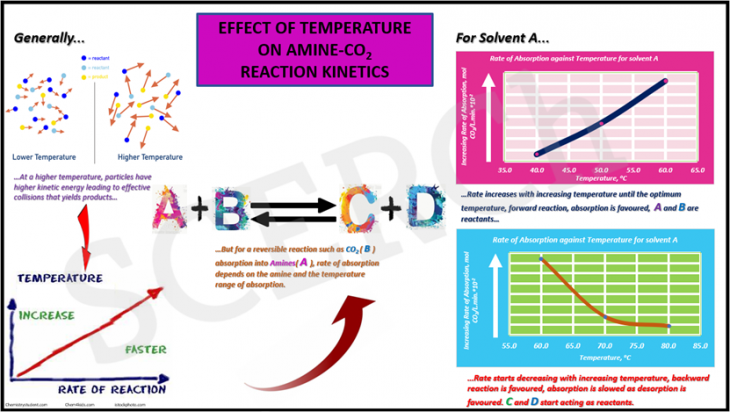

Effect of Temperature on Amine-CO2 Reaction Kinetics

In general, rate of chemical absorption of CO2 increases with increasing temperature. This is because an increase in temperature will raise the average kinetic energy of the reactant molecules. Therefore, a greater proportion of molecules will have the minimum energy necessary for an effective collision that yields the product. This was observed in our experiments for the absorption temperature regime (40 - 60 ºC)...

Read More

Exhaust Gas Dust

Flue gases from coal fired power plants, cement and iron and steel industries consist of impurities such as NOx, O2, and SOx. CO2 is considered as the gas of interest because it needs to be separated and removed from the gas stream. These exhaust gas impurities have varying effects on the stability of amine and capture process in an amine-based post combustion CO2 capture process. In this episode, we will pivot our discussions on the influence of the dust content on amine stability and the process performance in amine-based post combustion CO2 capture process.

Read More